Understanding PP Sheets: Versatile Solutions For Numerous Industries

Introduction to PP Sheets

Polypropylene (PP) sheets are a form of thermoplastic polymer that have found extensive applications across various industries due to their unique characteristics. Known for their excellent chemical resistance, durability, and lightweight nature, these sheets are ideal for both industrial and consumer use. The manufacturing process involves polymerization of propylene monomers, resulting in a material that boasts high flexural strength, tensile strength, and excellent impact resistance. As a result, polypropylene sheets are used in a multitude of applications, ranging from packaging and automotive parts to medical equipment and construction projects.

One of the key advantages of Pulkit Plastic Products is their versatility. They can be easily fabricated, customized, and molded into various shapes, making them suitable for applications that require specific dimensions or features. Additionally, they can be easily printed on, which is crucial for branding and identification purposes. With a growing focus on sustainability, the recyclability of polypropylene also enhances its appeal, allowing for eco-friendly practices in product development and waste management.

The Properties of PP Sheets

PP sheets exhibit a range of properties that make them highly suitable for diverse applications. Firstly, they are inherently resistant to moisture, which makes them popular for use in environments where exposure to water or chemicals is a concern. This characteristic is particularly beneficial in packaging applications where maintaining product integrity is essential. Furthermore, PP sheets are resistant to solvents and acids, ensuring their longevity even in harsh conditions.

Another noteworthy property of polypropylene sheets is their lightweight nature. Weighing significantly less than many alternatives, these sheets help reduce transportation and handling costs. Additionally, their ease of fabrication adds to their appeal: they can be cut, welded, and formed into various shapes, providing flexibility in design and construction. Another important aspect is their temperature resistance, capable of enduring a temperature range between -20°C to 100°C (-4°F to 212°F). This capability allows them to be used in a variety of climatic conditions without compromising their structural integrity.

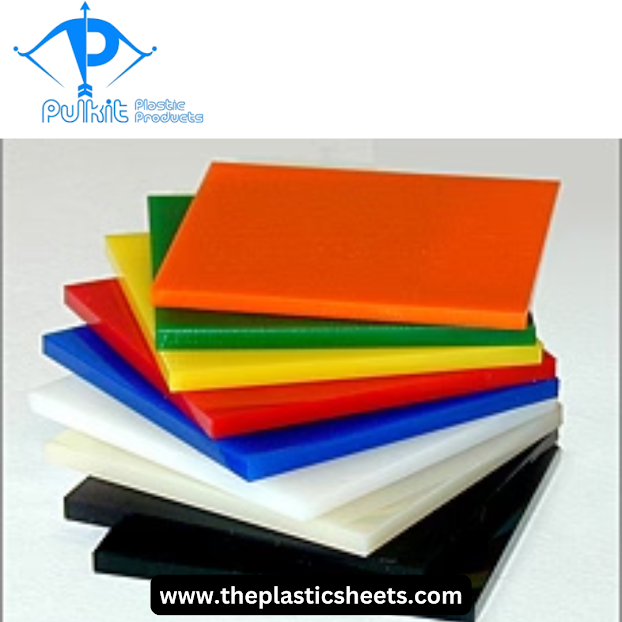

Moreover, PP sheets are available in both opaque and transparent varieties, catering to a broad spectrum of visual and aesthetic requirements. The ability to customize color options also makes them suitable for applications where color coding is necessary, such as in the manufacturing and packaging sectors.

Applications of PP Sheets

The versatile nature of PP sheet price has led to their widespread adoption in numerous industries. In the packaging industry, PP sheets are used to produce containers, boxes, and trays. Their lightweight and moisture-resistant properties ensure the durability and preservation of products during storage and transport. They are particularly valued in food packaging due to their non-toxic nature, making them safe for consumer use.

In the automotive sector, polypropylene sheets serve multiple purposes, including interior components, dashboards, and trim pieces. Their lightweight characteristics contribute to improved fuel efficiency by minimizing overall vehicle weight. Additionally, these sheets are resistant to scratches, further enhancing aesthetics and longevity.

Furthermore, PP sheets are prominently used in the medical field for manufacturing surgical trays, equipment covers, and disposable items due to their sterilization capabilities. Their chemical resistance also makes them suitable for laboratory applications where harmful substances may be present. In construction, these sheets are applied in roofing, storage solutions, and as protective barriers in various settings.

Moreover, the rise of environmentally conscious practices has amplified the use of recycled polypropylene sheets in sectors focused on sustainability. Manufacturers are increasingly integrating reclaimed polypropylene into their product lines, promoting a circular economy model within the industry.

Analyzing PP Sheet Price

When considering the procurement of PP sheets, potential buyers often inquire about PP sheet price as a deciding factor. The price of polypropylene sheets can vary depending on several factors, including the thickness, size, color, and finish of the sheets. Additionally, the quantity ordered can significantly influence the overall cost; bulk purchases typically offer lower per-unit prices due to economies of scale.

On average, consumers can expect to pay between $1 to $5 per square foot for standard polypropylene sheets, whereas customized or specialized sheets may cost more based on specific features or requirements. While it’s essential to focus on upfront costs, potential buyers should also evaluate the longevity and usability of the sheets, as investing in higher-quality materials can yield long-term cost savings through improved durability and reduced replacement frequency.

Furthermore, when comparing prices, it is valuable to consider the reputation and reliability of polypropylene sheets suppliers. Engaging with established suppliers known for quality products may lead to slightly higher upfront costs, but the trade-off often lies in reliability, consistency, and superior customer service.

Finding Reliable Polypropylene Sheets Manufacturers

Given the various applications and rising demand for PP sheets, businesses need to identify trustworthy polypropylene sheets manufacturers that can deliver high-quality products consistently. One effective strategy is to seek suppliers with certifications, such as ISO 9001, which indicates a commitment to quality management systems. Reading customer reviews and testimonials can provide insight into supplier reliability, product performance, and customer service experiences.

Collaboration with well-established manufacturers often provides additional benefits, including access to technical support and customization options. Many suppliers offer sample products to ensure compatibility with specific project requirements, allowing businesses to evaluate quality before committing to larger orders.

Moreover, given the increased focus on sustainability, partnering with manufacturers that prioritize eco-friendly practices can enhance corporate responsibility initiatives. This includes using recycled materials and promoting manufacturing processes that minimize waste and energy consumption.

To maximize value, consider establishing long-term relationships with suppliers. Consistent partnerships can lead to negotiation opportunities for lower prices, improved consistency in service, and early access to new product offerings.

Innovations in PP Sheet Technology

The Polypropylene sheets suppliers industry has seen numerous technological advancements aimed at enhancing product performance and expanding applications. One of the most promising developments is the introduction of multi-layered polypropylene sheets. These sheets incorporate various polymer layers to create enhanced properties, such as improved barrier resistance and moisture control.

Additionally, advancements in blending technologies allow for the inclusion of other polymers and additives to achieve specific performance characteristics. For instance, incorporating flame retardants or UV stabilizers can enable PP sheets to meet industry-specific safety standards, making them suitable for use in more specialized applications.

Another notable innovation includes the development of surface treatments that enhance adhesion and compatibility with inks and coatings, thus increasing the potential for branding and customization in packaging applications. This adaptability allows businesses to utilize PP sheets for unique marketing strategies while maintaining product integrity.

The trend toward sustainability has also led to innovations in recycled polypropylene sheets, utilizing reclaimed materials while maintaining high-quality performance standards. As consumer demand for eco-friendly products continues to rise, manufacturers are investing in research to further enhance the performance of recycled PP sheets.

Environmental Considerations and Recycling

As industries become increasingly aware of their environmental impact, the focus on sustainable practices has gained significant momentum. Polypropylene, being a recyclable material, allows for the recovery and reuse of resources, reducing waste generated in production processes. Through proper recycling programs, waste PP sheets can be reprocessed into new products, contributing to a circular economy.

Many manufacturers are embracing this trend by developing processes for reintroducing recycled polypropylene into their production lines. As a result, the demand for products made from recycled materials is on the rise, with companies finding strong market advantages in offering sustainable solutions.

Moreover, effective waste management strategies have been developed to minimize environmental impact while producing new polypropylene products. By investing in cleaner technologies and eco-friendly practices, companies not only reduce their carbon footprint but also appeal to an increasingly eco-conscious consumer base.

As regulations regarding plastic usage evolve, companies involved in the PP sheet production chain are re-evaluating their practices and seeking innovative ways to meet sustainability goals without compromising product quality and affordability.

Conclusion

PP sheets serve as a robust and versatile solution across many sectors, bolstered by their durability, lightweight nature, and excellent chemical resistance. With numerous applications in packaging, automotive, medical, and construction industries, their importance continues to grow. Companies looking to procure polypropylene sheets must consider various aspects such as price, quality, and supplier reliability to ensure they make informed decisions.

The advancements in Polypropylene sheets manufacturers technology and the increasing emphasis on sustainability further position these sheets as crucial components in modern manufacturing and development strategies. By embracing innovative practices, businesses can contribute to a healthier environment while catering to consumer demands for high-quality, versatile products.

Frequently Asked Questions

What is the average price range for PP sheets?

- The PP sheet price typically ranges between $1 to $5 per square foot, depending on factors such as thickness, size, and customization options.

What distinguishes polypropylene sheets from other plastic materials?

- Polypropylene sheets stand out due to their excellent chemical resistance, lightweight nature, and moisture-resistant properties, making them suitable for various applications in industries like packaging and automotive.

How can I find reliable polypropylene sheets suppliers?

- Look for suppliers with established reputations, relevant certifications, and strong customer reviews. Engaging with manufacturers who prioritize quality assurance is crucial for consistent product performance.

Are PP sheets recyclable?

- Yes, polypropylene sheets are recyclable, and many manufacturers are incorporating recycling practices to create sustainable products, contributing to a circular economy while minimizing environmental impact.

Comments

Post a Comment