Understanding PP Sheets: Versatile Solutions for Modern Applications

Introduction to PP Sheets

Polypropylene sheets, commonly referred to as PP sheets, are made from polypropylene, a thermoplastic polymer known for its versatility and durability. These sheets have gained significant traction across various industries due to their lightweight, chemical resistance, and ability to withstand a broad range of temperatures. In recent years, the demand for polypropylene sheets in India has surged as businesses seek reliable materials for packaging, construction, and a myriad of other applications. The unique qualities of Pulkit Plastic Products make them not just a functional solution but also an innovative answer to evolving material needs.

Characteristics and Benefits of PP Sheets

PP sheets boast several remarkable characteristics that contribute to their popularity. One of their primary advantages is their exceptional resistance to moisture, which makes them ideal for outdoor applications or environments prone to humidity. Additionally, they demonstrate high resistance to a spectrum of chemicals, including acids and bases, making them suitable for industries such as pharmaceuticals and food processing, where hygiene and safety are paramount.

Another significant characteristic of polypropylene sheets is their lightweight nature. Compared to traditional materials, such as metal or glass, PP sheets are easier to handle, transport, and install. This property can lead to reduced shipping costs and lower overall project costs due to easier installation processes. Furthermore, their durability ensures a longer lifespan, translating into fewer replacements and lower maintenance costs over time.

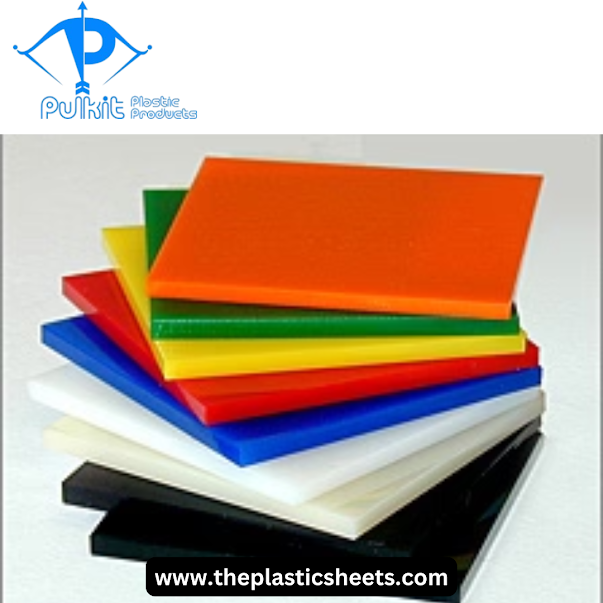

Moreover, PP sheets can be manufactured in various colors, thicknesses, and finishes, providing businesses with design flexibility. Whether used for functional or aesthetic purposes, this adaptability allows companies to tailor their sheet solutions to meet specific project requirements seamlessly.

Applications of PP Sheets in Various Industries

The range of applications for Polypropylene sheets in India is extensive. One of the most common uses can be found in the packaging industry. PP sheets are often utilized for creating packaging materials, containers, and dividers that safeguard products during transport. Their lightweight structure, combined with strength and durability, allows them to protect goods effectively while being easy to handle.

In the construction sector, PP sheets are gaining popularity due to their water resistance and durability. They are frequently used as vapor barriers, insulation, and roof coverings. Their ability to withstand weather elements and resist moisture makes them a dependable choice for various construction projects, from residential buildings to commercial facilities.

The automotive industry is another sector where PP sheets find widespread use. They are often used for interior components, dashboards, and even exterior panels. The lightweight nature of these sheets contributes to fuel efficiency, as lighter cars tend to consume less fuel. Additionally, the ability to mold and shape PP sheets allows for innovation in vehicle design, enhancing both functionality and aesthetics.

PP sheets also play a significant role in the advertising and signage industry. Their ability to be printed on while maintaining durability against environmental factors makes them an ideal choice for outdoor and indoor signage. From billboards to promotional displays, PP sheets can effectively convey messages while withstanding the elements.

Overview of the Market for Polypropylene Sheets in India

As the demand for polypropylene sheets grows, the market landscape in India is evolving rapidly. Several manufacturers and suppliers are entering the market, offering a plethora of options for businesses looking to procure these materials. Both local and international players are actively competing, contributing to a dynamic marketplace that focuses on quality and innovation.

In India, various regions are known for their manufacturing capabilities of polypropylene products. States like Gujarat, Maharashtra, and Tamil Nadu host several manufacturers that specialize in PP sheets and related products. These manufacturers often leverage advanced technologies to ensure that their products meet international standards, catering to the requirements of diverse industries.

The increasing awareness of environmental sustainability is also shaping the demand for polypropylene sheets. Businesses are beginning to recognize the importance of using recyclable materials in their operations, and PP sheets offer an eco-friendly solution compatible with sustainable practices. Such trends could further boost the demand for polypropylene sheets and create opportunities for manufacturers to innovate and expand their product lines.

Cost Factors Associated with PP Sheets

One of the critical considerations when evaluating materials for projects is cost. Understanding the cost of plastic sheets, particularly polypropylene sheets, involves taking several factors into account. The price point may vary based on the thickness, size, and manufacturing processes utilized. Generally, PP sheets are cost-effective solutions compared to many alternatives, particularly when calculating the total cost of ownership, which includes factors like durability and maintenance.

In India, the Cost of plastic sheets can fluctuate based on market conditions, raw material costs, demand, and supply dynamics. As the global polypropylene market experiences changes, these fluctuations can impact local pricing. Consequently, businesses need to stay informed about current market trends to ensure they are making competitively priced purchases.

When comparing costs, it is also vital to consider the benefits that polypropylene sheets provide over time. Their durability and low maintenance requirements contribute to long-term savings, as businesses can expect to replace them less frequently compared to lower-quality alternatives. Additionally, organizations can often negotiate bulk buying rates with suppliers, further minimizing costs and maximizing budgets.

Environmental Considerations and Sustainability

As environmental issues are becoming increasingly important, the push for sustainable materials is a focal point for industries globally. Polypropylene sheets hold a significant advantage in this domain due to their recyclable nature. Once they reach the end of their life cycle, PP sheets can be repurposed, minimizing waste and reducing the need for new raw materials. This characteristic makes polypropylenes an attractive option for companies prioritizing environmental responsibility.

Moreover, the production processes for polypropylene sheets are continually evolving, with a growing emphasis on eco-friendly practices. Manufacturers are investing in technologies that limit energy consumption and utilize sustainable practices in their operations. By focusing on reducing the carbon footprint in their production methods, suppliers help enhance the overall sustainability of PP sheets.

Companies that prioritize using environmentally friendly materials are likely to resonate well with consumers who are concerned about sustainability. By integrating polypropylene sheets into their operations, businesses can not only reduce their environmental impact but also improve their brand image and gain market share among eco-conscious consumers.

Innovations in the Production of PP Sheets

Innovation plays a pivotal role in the development of polypropylene sheets. As technology advances, manufacturers are constantly finding new ways to enhance the performance and versatility of these materials. For instance, incorporating additives during the manufacturing process can improve properties such as UV resistance, flame retardancy, and impact resistance. These enhancements allow polypropylene sheets to be used in an even wider range of applications.

Additionally, improved methods for customization enable manufacturers to offer tailored solutions for unique project requirements. By adjusting thickness, color, size, and finish according to specific client needs, manufacturers can create products that better meet the demands of various industries. This customization capability is especially valuable for businesses looking for specific applications that require unique physical properties or visual aesthetics.

The integration of digital technology into the production process is also paving the way for enhanced efficiency and quality control. Automation and advanced monitoring systems are streamlining operations, resulting in improved accuracy and consistency in the production of polypropylene sheets. These innovations ensure that manufacturers can cater to increasing demand while maintaining high-quality standards.

Conclusion

The PP price in India are an essential component in modern manufacturing and construction, providing a durable, versatile, and cost-effective solution for a wide array of applications. Their lightweight nature, chemical resistance, and recyclability make them ideal for use in industries ranging from packaging to automotive. As awareness of sustainability continues to grow, the demand for environmentally friendly materials like PP sheets will increase, prompting ongoing advancements in their production and application.

In India, the market for polypropylene sheets is rapidly evolving, with numerous manufacturers catering to the rising demand. As businesses navigate the complexities of supply chains and costs, staying informed about market trends and innovations will be crucial. Ultimately, the ability to leverage the unique characteristics of PP sheets while prioritizing quality, environmental responsibility, and cost-effectiveness can provide companies with a competitive edge in their respective sectors.

Frequently Asked Questions

What are PP sheets made from?

- PP sheets are made from polypropylene, a type of thermoplastic polymer known for its lightweight, durability, and resistance to moisture and chemicals.

What industries commonly use polypropylene sheets?

- PP sheets are utilized across various industries, including packaging, construction, automotive, agriculture, and advertising, thanks to their versatility and durability.

How does the cost of polypropylene sheets compare to other materials?

- While the cost of polypropylene sheets changes based on factors like thickness and size, they are often more cost-effective than heavier materials like metal or glass, particularly in terms of total lifecycle costs.

Are polypropylene sheets recyclable?

- Yes, polypropylene sheets are recyclable, making them an eco-friendly choice for businesses looking to minimize their environmental impact. They can be repurposed after their initial use, reducing waste and supporting sustainable practices.

Comments

Post a Comment